제품 끝view

The Artillery Sidewinder X3 Plus is a high-performance 3D printer designed for both hobbyists and professionals, offering a large build volume and advanced features for efficient and precise 3D printing.

그림 1: 앞쪽 view of the Artillery Sidewinder X3 Plus 3D Printer, showcasing its robust frame and integrated control panel.

주요 특징

- Large Build Size: 300mm × 300mm × 400mm (11.8in × 11.8in × 15.7in) for greater creative freedom.

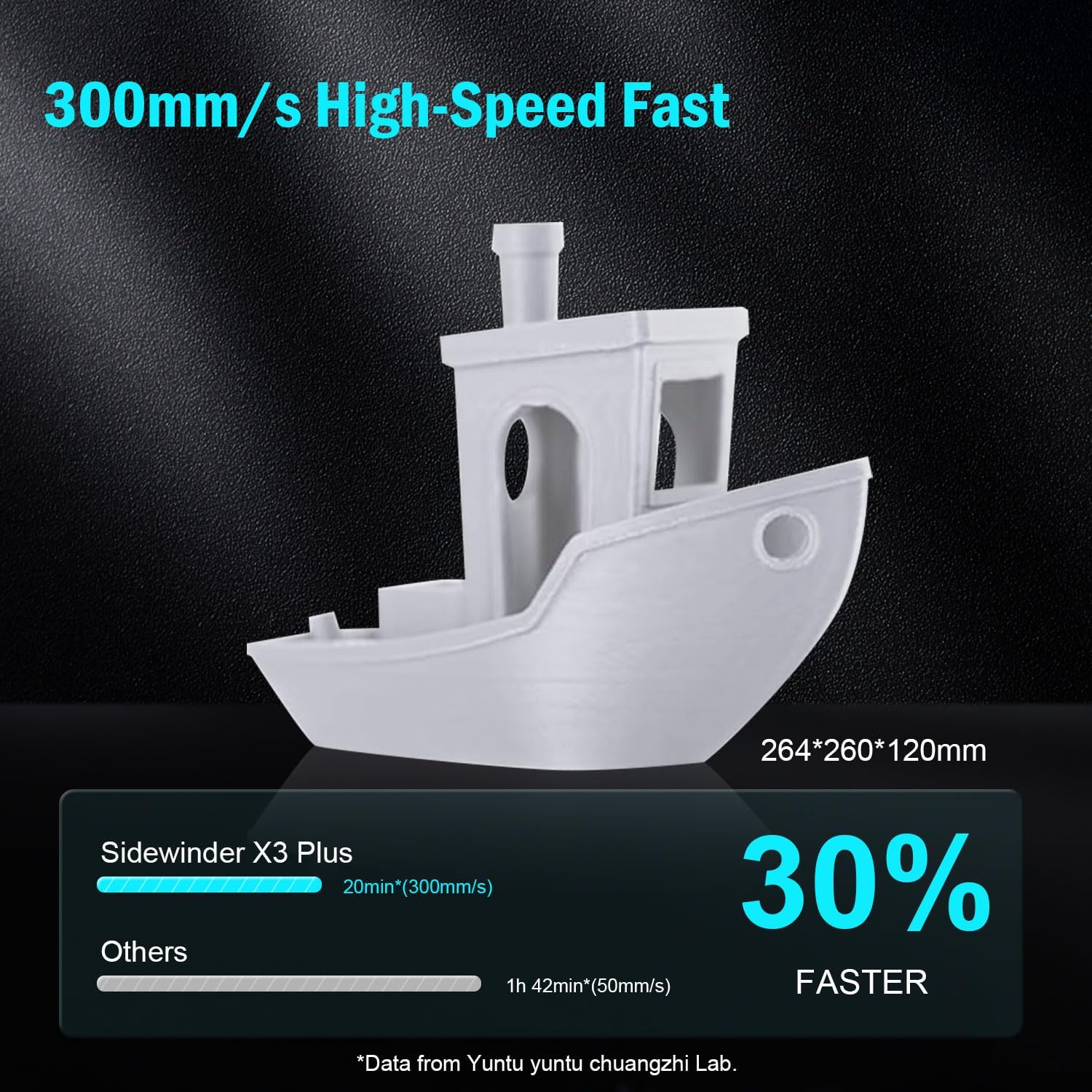

- Ultra-Quiet High-Speed Printing: Achieves speeds up to 300 mm/s with 0.1 mm precision.

- Upgraded 300°C High-Temperature Nozzle: Supports various filaments including PLA, TPU, PETG, ABS, and Nylon, with automatic nozzle cleaning.

- 49-Point Auto Bed Leveling: Ensures quick and accurate leveling of the build platform.

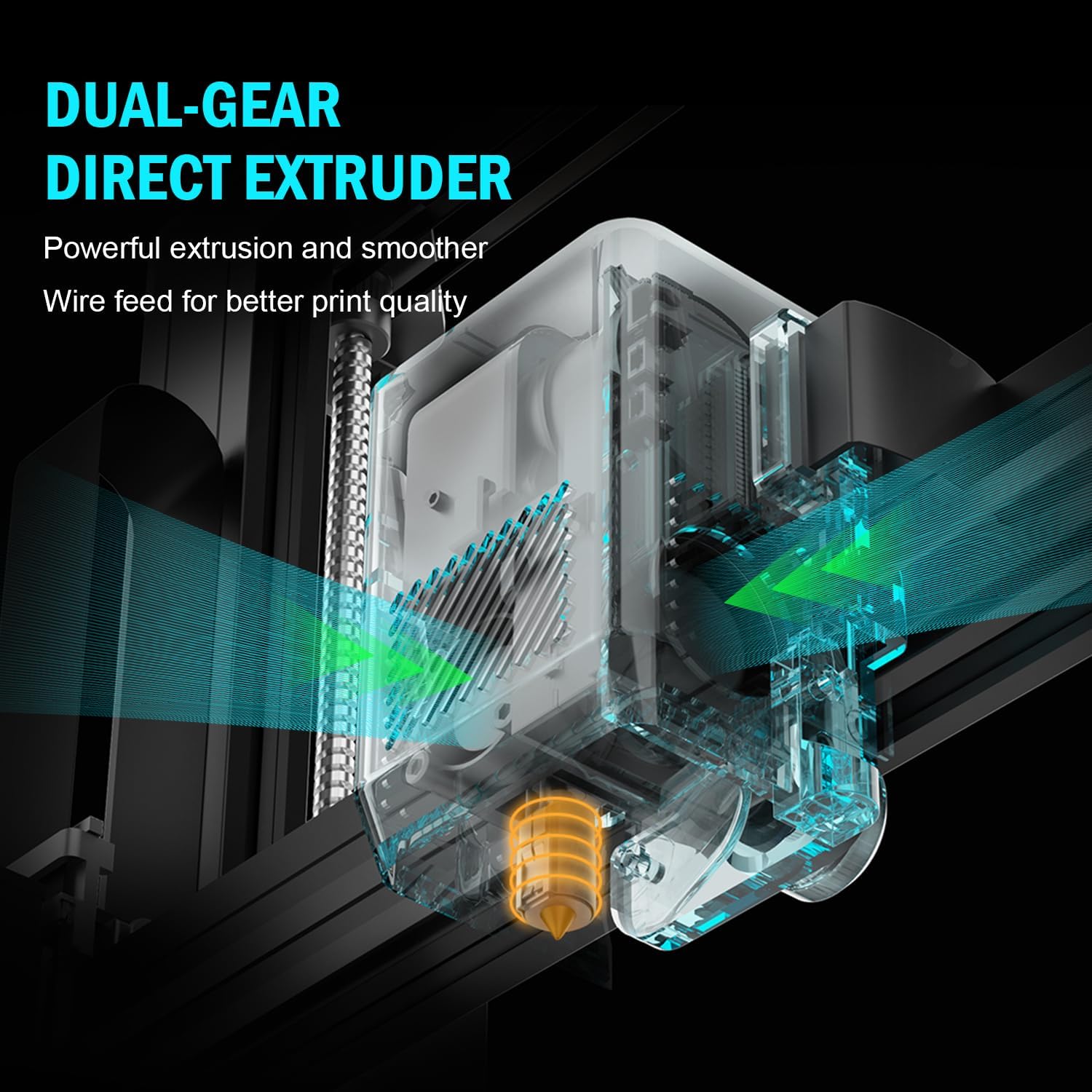

- Dual-Gear Direct Extruder: Provides powerful extrusion and smoother filament feeding for improved print quality.

- Resume Printing Function: Detects filament runout/breakage or power loss and resumes printing after recovery.

- Dual Z-axes & Dual Motors: Ensures stability and higher printing accuracy through coordinated movement.

그림 2: Illustration demonstrating the large print volume of the Sidewinder X3 Plus, capable of accommodating substantial models.

그림 3: Visual representation of the Sidewinder X3 Plus's high-speed printing capability, showing a printed boat model.

그림 4: 클로즈업 view of the all-metal hotend and automatic cleaning nozzle, highlighting its high-temperature capabilities.

그림 5: Diagram illustrating the 49-point smart auto-leveling system on the print bed, simplifying the leveling process.

그림 6: 내부 view of the dual-gear direct extruder, showing the gears that ensure consistent filament flow.

그림 7: Depiction of the dual Z-axes and dual motors system, highlighting their role in enhancing print stability and precision.

설치 가이드

The Artillery Sidewinder X3 Plus is designed for quick assembly. Follow these general steps for initial setup:

- 짐 풀기: Carefully remove all components from the packaging. Verify all parts listed in the packing list are present.

- 기본 조립: Place the printer base on a stable, level surface.

- 갠트리 설치: Attach the gantry (Z-axis frame) to the base. Ensure all screws are securely fastened.

- 배선 연결: Connect all necessary cables, including power, motor, and sensor cables, according to the labels.

- 필라멘트 홀더: 필라멘트 홀더를 장착하세요.

- 초기 전원 켜기: 전원 코드를 연결하고 프린터를 켭니다.

- 자동 레벨링: Perform the 49-point auto bed leveling procedure as prompted by the printer's interface. This is crucial for successful first prints.

그림 8: Visual guide showing the four main steps for assembling the Artillery Sidewinder X3 Plus, indicating a straightforward setup process.

작동 지침

필라멘트로드

- Ensure the hotend is preheated to the appropriate temperature for your filament type (e.g., 200°C for PLA).

- Insert the filament into the extruder's input hole.

- Push the filament until it is gripped by the extruder gears and begins to feed through the hotend.

- Confirm filament is extruding smoothly from the nozzle.

인쇄 시작

- Prepare your 3D model using slicing software (e.g., Cura, PrusaSlicer) and save it as a G-code file USB 드라이브 또는 SD 카드에 저장하세요.

- USB 드라이브/SD 카드를 프린터의 지정된 슬롯에 삽입하십시오.

- Navigate the printer's touchscreen interface to select the desired G-code file.

- Confirm print settings and initiate the print. The printer will automatically preheat and begin printing.

그림 9: Image showing the 4.3-inch touchscreen interface of the Sidewinder X3 Plus, demonstrating user interaction for print control.

Removing a Print

- Allow the print bed to cool down completely after the print finishes.

- Gently flex the PEI magnetic print platform to detach the printed object. Avoid using excessive force or sharp tools to prevent damage to the print surface.

유지

Regular maintenance ensures optimal performance and longevity of your Artillery Sidewinder X3 Plus.

- 프린트 베드를 청소하세요: 출력 후에는 매번 출력 표면을 이소프로필 알코올로 닦아 잔여물을 제거하고 다음 출력 시 접착력이 유지되도록 하십시오.

- 노즐 청소: The printer features an automatic cleaning nozzle. However, inspect the nozzle periodically for clogs or wear. If necessary, perform a cold pull or replace the nozzle.

- Lubricate Z-axis Lead Screws: Apply a small amount of lithium grease or similar lubricant to the Z-axis lead screws every few weeks, depending on usage, to ensure smooth vertical movement.

- 벨트와 풀리를 점검하세요: Periodically inspect the X and Y axis belts for proper tension and wear. Ensure pulleys are clean and move freely.

- 펌웨어 업데이트: 공식 포병 정보를 확인하세요 web프린터에 최신 기능과 버그 수정 사항이 적용되도록 펌웨어 업데이트가 있는지 해당 사이트를 확인하십시오.

일반적인 문제 해결

| 문제 | 가능한 원인 | 해결책 |

|---|---|---|

| 필라멘트가 압출되지 않음 | 노즐 막힘, 필라멘트 엉킴, 온도 오류. | Clean the nozzle, check filament path, verify hotend temperature. |

| 침대 접착력 불량 | 베드 수평 불량, 출력 표면 오염, 베드 온도 설정 오류. | Perform auto-leveling, clean print bed with isopropyl alcohol, adjust bed temperature. |

| 레이어 이동 | Loose belts, motor issues, print speed too high. | Check and tighten X/Y axis belts, inspect motor connections, reduce print speed. |

| Printer is excessively loud | Loose components, fan noise, worn bearings. | Inspect for loose screws, check fan operation, lubricate moving parts. |

| "Thermal runaway detected" error | Faulty thermistor, loose wiring to hotend/bed, heater cartridge issue. | Immediately power off the printer. Check all wiring connections to the hotend and heated bed. Contact support if issue persists. |

| "Error: home Y failed" or similar homing errors | Obstructed endstop switch, loose motor cable, faulty sensor. | Check for obstructions, ensure all motor and endstop cables are securely connected. Restart printer. |

기술 사양

| 특징 | 세부 사항 |

|---|---|

| 제품 치수 | 20 x 19.4 x 25.6인치(508 x 493 x 650mm) |

| 품목 무게 | 36.6파운드(16.6kg) |

| 볼륨을 빌드하세요 | 300 x 300 x 400mm(11.8 x 11.8 x 15.7인치) |

| 인쇄 속도 | 최대 300mm/s |

| 노즐 온도 | 최대 300°C |

| 베드 레벨링 | 49포인트 자동 베드 레벨링 |

| 압출기 유형 | 듀얼 기어 다이렉트 익스트루더 |

| 지원되는 필라멘트 | PLA, TPU, PETG, ABS, 나일론 |

| 연결성 | USB, SD 카드 |

| 재료 | 금속 |

| 색상 | 검은색 |

보증 및 지원

For warranty information and technical support, please refer to the official Artillery web사이트를 방문하거나 고객 서비스에 직접 문의하세요. 보증 청구를 위해 구매 증빙 자료로 구매 영수증을 보관하세요.

제조업체: 포

공식적인 Web대지: www.artillery3d.com (참고: 이것은 플레이스홀더입니다. URL자세한 내용은 해당 제조업체의 자료를 참조하십시오. web지원 사이트입니다.)